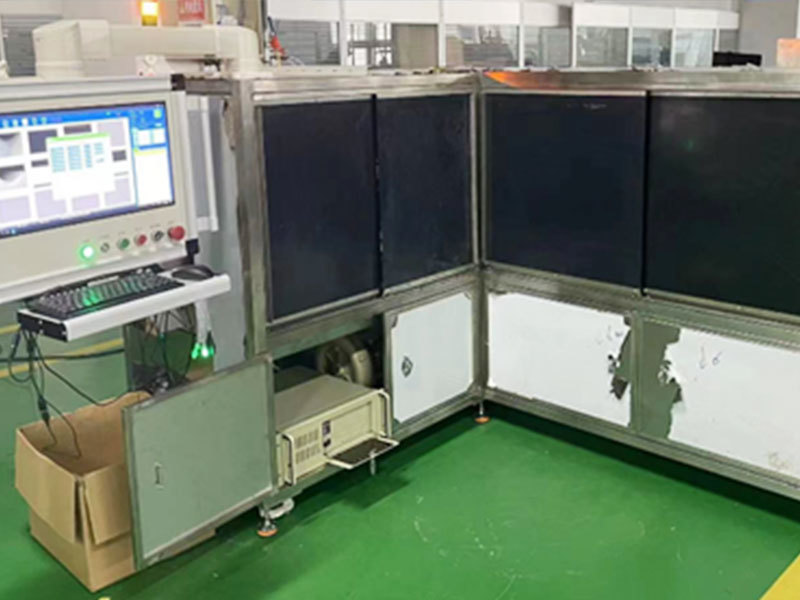

Automatic medical small rubber sleeve visual inspection machine

Keywords:

Automatic medical small rubber sleeve visual inspection machine

Classification:

Product Introduction

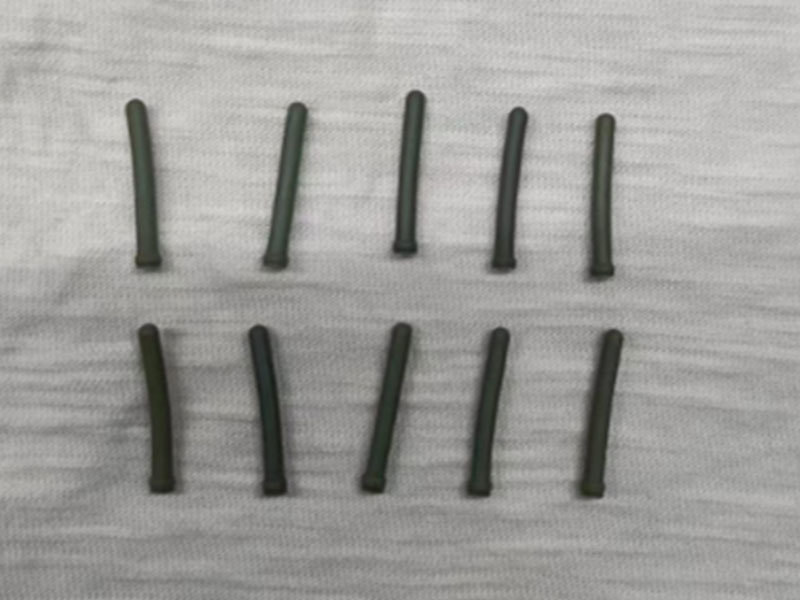

The automatic medical small rubber sleeve visual inspection machine is divided into four units: feeding unit, detection unit, defective product rejection unit and discharging unit. The detection machine adopts the method of oscillation + tooth belt feeding, and inspects the defects such as lack of material, bending, flash, discoloration, and dirt produced by the medical small rubber sleeve in the production process, and the detection machine is an image detection equipment based on the industrial camera, which has stable performance and high image accuracy, which improves production efficiency and saves labor costs for customers. The equipment will detect the outer surface of the detected object, and automatically reject the unqualified products, and the qualified products will be automatically counted and bagged, and the products only need to be sealed and packed manually.

▎Scope of application:

Small rubber sleeve

▎Performance characteristics:

● Real-time storage of detection data, detection results, real-time images, and operating status are dynamically displayed on the display

● Modular design of the equipment, simple interface operation, stable system, simple maintenance, easy cleaning, in line with GMP standards, the overall equipment needs to meet the standards of 100,000-level purification workshop

● Automatic and accurate positioning of defective products, automatic statistics of qualified products for high-speed rejection, and can be diverted to the designated collection container

● The detection speed is 1200 pcs/min

Product Message

Building 1, Liandong U Valley, No. 36, Jing3 Road, High-tech Zone, Yantai City, Shandong

Contact Person:Molly Sun / Sun Mingming